Cast Iron Radiator Restoration

Restoration & Electric conversion

ECORAD offers two approaches to respond effectively to your challenge.

Restoration

Electric conversion

Complete cast iron radiator restoration. To update the central water and steam system.

Restored antique cast iron radiators deliver optimal performance by stripping away layers of paint and cleaning the interior, both of which improve radiant heat transfer.

- Preserves the aesthetic value and the heritage of the heating system already in place.

- Allows an optimal integration to the central water or steam heating system of the building being restored.

- Optimizes the current system by possible addition, replacement or resizing of radiators.

- Limits restoration costs by reusing original radiators.

- Tangibly and measurably reduces energy consumption.

- Provides complete peace of mind by reducing the risk of damage associated with aging equipment and by offering an eco-friendly solution.

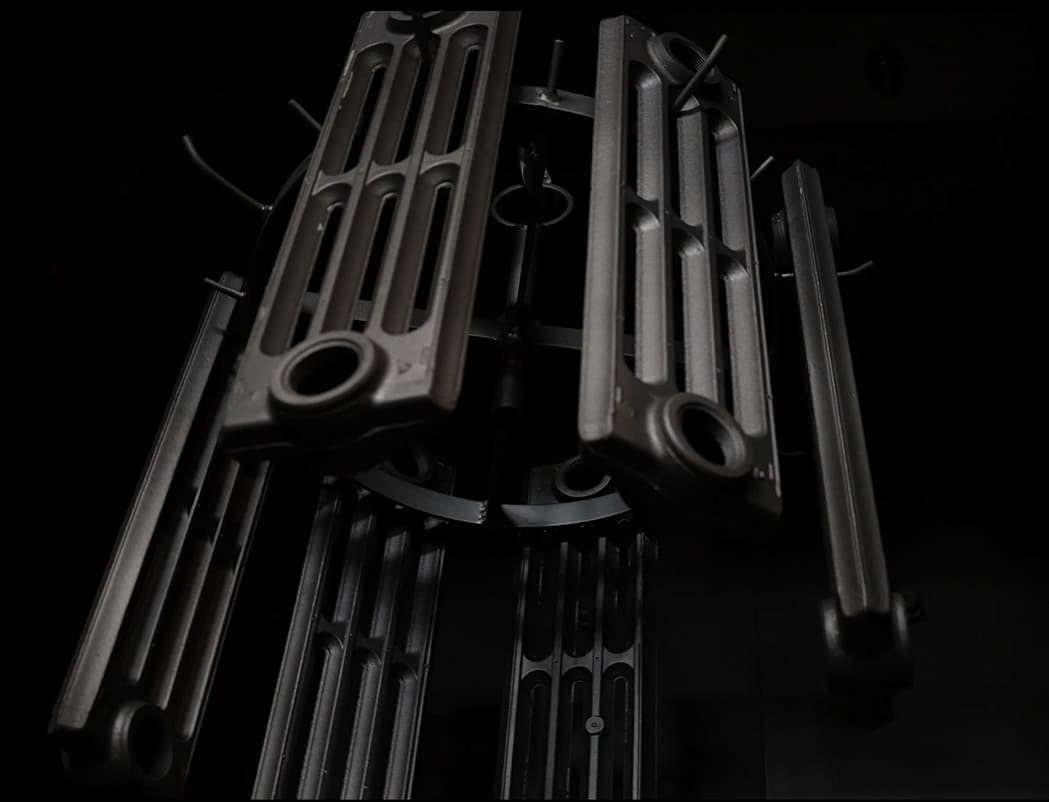

Unique Restoration Process

The restoration process we use to restore our original cast iron radiators has evolved over 15 years of research and development.

1

Paint Stripping

- Shot peening process

- Lead paint contaminants management

2

Disassembly

- Each radiator is disassembled into individual sections

- Worn joining nipples and gaskets are removed

3

Internal Cleaning

- Internal water pressure washing

- Resurfacing of the bearing surfaces of the seals

4

Reassembly

- Meticulously reassembled, section by section

- Repair, remove or replace faulty sections

- Using new joining nipples and fiber gaskets

5

Leak Test

- Pressure and immersion testing

6

Painting

- Spray acrylic enamel paint

7

Packaging

- Wrapped in cardboard and plastic

To propel the building into the era of building automation.

Combined with the cast iron radiator restoration the optional electric conversion offers many modern benefits. Innovations developed by ECORAD make it possible to recover or even surpass original performance of cast-iron radiators.

- Offers a transition from central heating management to flexible multi-zone management with individual settings for each unit.

- Allows the demand on the power grid to be scheduled around peak hours and rates as needed to reduce consumption.

- Easily integrates into modern building management like any other building automation equipment or system.

- Applicable to virtually all cast-iron radiators already installed in historic buildings.

- Eliminates boilers and obsolete piping subject to recurring maintenance management and costs.

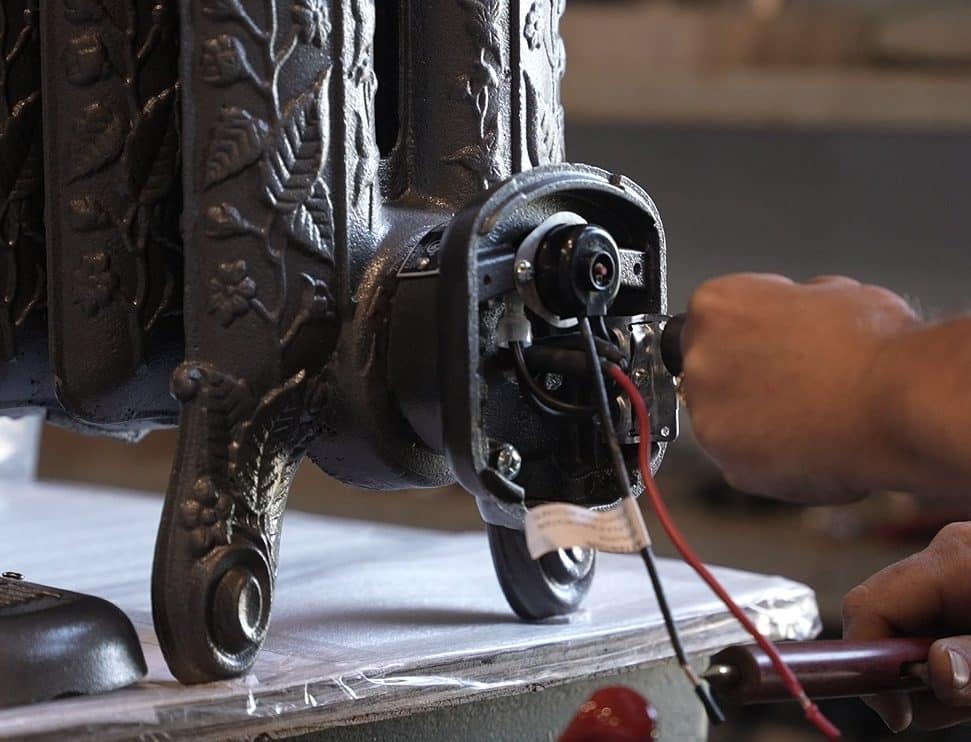

Electric Conversion Process

All cast iron radiators go through our rigorous cast iron radiator restoration process and are then:

1

Filled

Filled with a precise mix of water and anti-freeze.

2

Converted

Received a specially adapted electric element.

3

Sealed

Are permanently sealed.

4

Tested

Are tested in compliance with UL Standards.

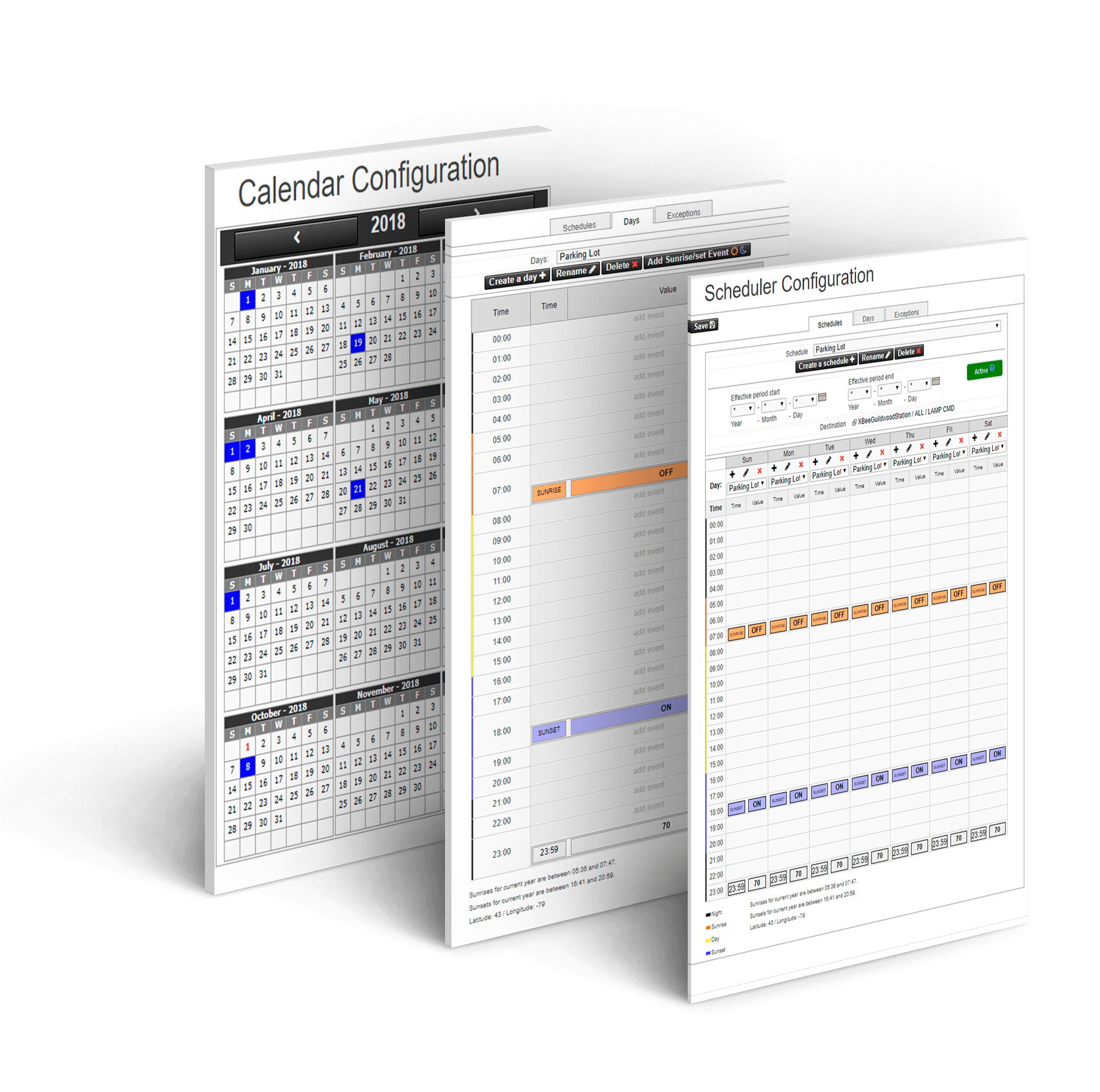

Management system for electrified Radiators

Combine the electric converted cast iron radiators with a management system to optimize the benefits.

ECORAD offers two managment options:

Optimum Intelligent System OE13

Manual Power Control System ME13

The Optimum OE13 is an intelligent management system for electrified ECORAD radiators.

This system combined with the expertise of ECORAD has the ability to maximize the inertia properties of cast iron radiators to consume the least amount of energy possible.

Available for all types of buildings regardless of heating energy installed. Programmable with user friendly software, allowing calendar and/or time schedules, the configuration and utilization is via an independent touch screen, a computer locally or remotely through the internet.

The internet option allows users via a password, to verify, change the settings and receive alerts by email. Free technical support for the first 12 months from the start.

Avantages

- Programmation considers outside temperature and usage of each area

- Power setpoint is adjustable

- Alerts are configurable

- Self-governing once programmed

- Stores data for up to four years

- Printable tables or graphs of history

- Startup is performed by an ECORAD technician

- Installation and connection must be done by a qualified electrician

The ME13 is a manual control system that offers a simple solution for budgetprojects to manage the energy consumption of the heating system with ECORAD electric.

Paired with web thermostats, it manages power according to predefined parameters. It rotates loads with load shedding to minimize power demands.

Designed for buildings with an installed heating power of less than 99 kW. It allows you to control 8 or 16 zones.

Avantages

- Less energy consumption

- Peak Energy Control

- Remote access and monitoring

Project evaluation

ECORAD. Your Cast Iron Radiator Conservation Partner.

In perfect synergy with you for the conservation of cast iron radiators

Conservation is not only part of our values and culture, it’s in our DNA. By sharing our knowledge and expertise, we can ensure the complete success of your project.

Concretely, here is what you can expect from ECORAD:

- A proactive, dynamic business relationship based on comprehensive support.

- Personalized assistance throughout the project from a no strings attached consultation to the post installation follow up.

- Access to the owners and other key personnel to answer any technical or even historical questions related to your project.