Hot water and steam cast iron radiators are not interchangeable. Understanding the differences between them is essential to avoid unforeseen and costly issues. In this blog post, we will explore what are the differences and why it is essential to know the differences between hot water and steam cast iron radiators.

Example of a costly mistake made by installing non-compatible steam radiators on a hot water system. The contractor was not aware of the differences between steam and hot water radiators, resulting in a leaky, inefficient, and maintenance-intensive heating system. He eventually installed bleeders on each section to bleed them manually.

First, let’s examine the differences in water vs. steam flow.

While most hot water radiators can work on a steam system, the same is not true for steam radiators. Steam radiators cannot be used on hot water systems unless the sections at the top connect. As steam rises, it does not need to circulate, whereas water needs to circulate. Does that mean all steam radiators that do not connect at the top belong in landfills? No, they can be converted to electric radiators. The steam radiators connect at the top, great! But that’s not all, keep reading as they still need to be worked on.

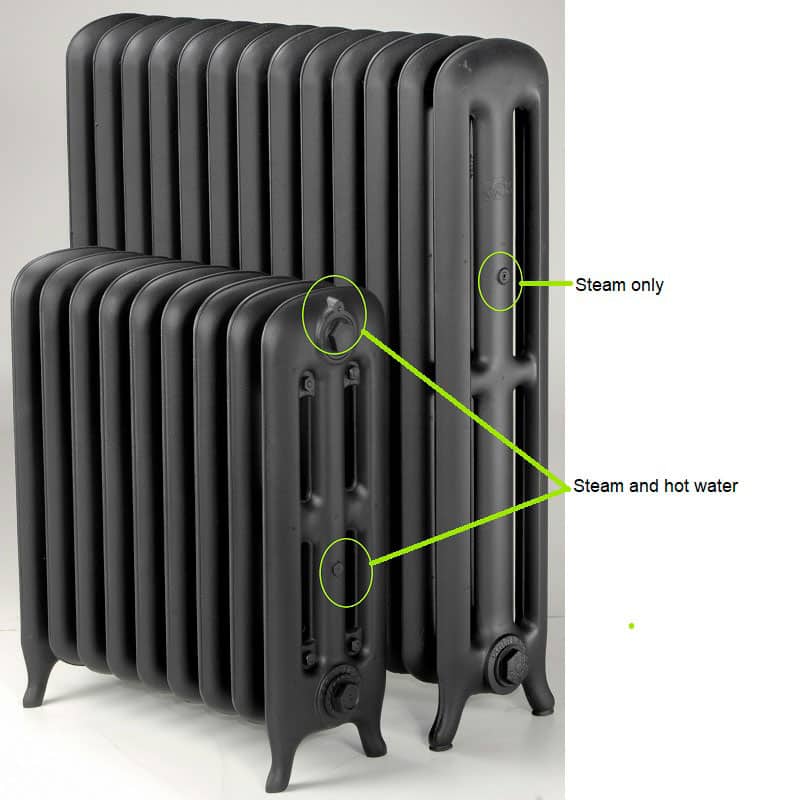

See the difference in the two pictures below.

The steam radiators connect at the top, great! But that’s not all.

Second, let’s discuss differences in vent location.

The diameter of the hole for the steam trap on steam radiators and the bleeder valve on hot water radiators is the same, and both must be located on the opposite end of the radiator from the inlet. The location of the steam trap hole on steam radiators is lower than the middle of the section, whereas the bleeder valve holes on hot water radiators are located at the top. See the difference in the picture below. Some radiators were casted with a nipple on the end section allowing the plumber to machine the hole according to the end use. So you can plug the steam trap hole and use the top hole for the bleeder.

Thirdly, let’s dive into the inner components. Inner components in steam radiators such as cast iron threaded nipples, gaskets and steel push nipples have a reduced life expectancy compared to those in hot water radiators. This is due to joints wearing faster as a result of high temperature and contrast. It’s important to note that installing a radiator previously used in a steam system onto a hot water system will result in major joint leaks, which is why restoration including new inner components is required.

In conclusion, it’s crucial to understand the differences between hot water and steam cast iron radiators to avoid costly mistakes. Furthermore, knowing why steam radiators need to be restored before installation on a hot water system is necessary to prevent leak issues and ensure a long-lasting installation. Remember that all unused steam or hot water cast iron radiators can be converted to electric independent radiators; they are not meant for the scrap yard. With these considerations in mind, you will be better equipped to oversee challenges associated with reusing steam cast iron radiators on a hot water system and save ones that cannot be reused.

ECORAD teams are empowered to detect these kinds of issues, providing you with peace of mind, ensuring that cast iron radiators operate effectively, efficiently and with longevity.